- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Home

>

Products > Hybird Stepper Motor Driver > 2 Phase Hybrid Stepper Motor Driver > Ultra Smooth 2 Phase Hybrid Stepper Motor Driver

Products

- AC Servo Motor

- DC Servo Motor

- Closed Loop Stepper Motor

- Hybird Stepper Motor

- Hybird Stepper Motor Driver

- Closed Loop Stepper Motor Driver

- AC Servo Motor Driver

- Integrated Stepper Motor

- DC Servo Motor Driver

- Screw Motor

- RS485 or CAN or Ethercat Bus type Stepper Driver

- Planetary Reducer

- PLC Controller

- HMI Touch Screen

- Ethercat AC Servo Motor Driver Kit

- A8 AC Servo Motor Driver Kit

- Integrated Servo Motor

New Products

Pulse/RS485 750W/1000W/1001W 2500/3000RPM A8 High Accuracy STO ABZ AC Servo Motor Drivers Kit

Pulse/RS485 750W/1000W/1001W 2500/3000RPM A8 High Accuracy STO ABZ AC Servo Motor Drivers Kit Pulse/RS485 200W/400W/600W 2500/3000RPM A8 High Accuracy STO ABZ AC Servo Motor Drivers Kit

Pulse/RS485 200W/400W/600W 2500/3000RPM A8 High Accuracy STO ABZ AC Servo Motor Drivers Kit Pulse/RS485 50W/100W 2500/3000RPM A8 High Accuracy STO ABZ AC Servo Motor Drivers Kit

Pulse/RS485 50W/100W 2500/3000RPM A8 High Accuracy STO ABZ AC Servo Motor Drivers Kit EtherCAT 2Phase Nema24 4-Axis DC Closed Loop Stepper Motor Drivers Kit

EtherCAT 2Phase Nema24 4-Axis DC Closed Loop Stepper Motor Drivers Kit- All new products

Ultra Smooth 2 Phase Hybrid Stepper Motor Driver

LICHUAN® is Ultra Smooth 2 Phase Hybrid Stepper Motor Driver manufacturer and supplier in China.

Send Inquiry

Product Description

Low Price Quality Ultra Smooth 2 Phase Hybrid Stepper Motor Driver In Stock. LICHUAN® is Ultra Smooth 2 Phase Hybrid Stepper Motor Driver manufacturer and supplier in China.

Product Introduction

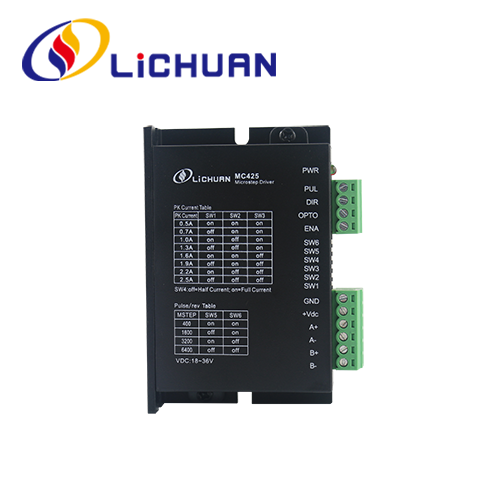

MC425E adopts the latest special motor control DSP chip and servo control technologies, completely solves step missing issues for open loop stepper motor, obviously improves motor performance at high speed, reduces heat generation and vibration of motor, increases processing speed and precision of machine, decreases power consumption. applies to 2 phase Nema17 hybrid stepper motors, is convenient for upgrading traditional stepper driver solutions and largely reduces cost.

MC425E Features

● Voltage input range: DC18V~36V

● Maximum peak current: 2.5A

● Subdivision range: 400~6400ppr

● Pulse form: pulse + direction

● Impulse response frequency: 0~200KHz

● Motor parameter auto-tuning function With protection functions such as over voltage, over current, tracking error out of tolerance, etc.

● More details Pls check driver manual on “download” catalog.

● Maximum peak current: 2.5A

● Subdivision range: 400~6400ppr

● Pulse form: pulse + direction

● Impulse response frequency: 0~200KHz

● Motor parameter auto-tuning function With protection functions such as over voltage, over current, tracking error out of tolerance, etc.

● More details Pls check driver manual on “download” catalog.

Technical parameter

● Voltage input range: DC18V~36V

● Maximum peak current:2.5A

● Subdivisionrange:400~6400ppr

● Pulse form: pulse +direction

● Impulse response frequency:0~200KHz

● Motor parameter auto-tuning function

● With protection functions such as overvoltage, overcurrent, tracking error out of tolerance, etc.

● Maximum peak current:2.5A

● Subdivisionrange:400~6400ppr

● Pulse form: pulse +direction

● Impulse response frequency:0~200KHz

● Motor parameter auto-tuning function

● With protection functions such as overvoltage, overcurrent, tracking error out of tolerance, etc.

Environmental parameters

● Storage temperature:-20 ℃~65 ℃

● Operating temperature:0 ℃~50 ℃

● Operating humidity:40~90%RH(non-condensing)

● Vibration frequency:less than 0.5G(4.9m/s2)10Hz~ 55Hz(discontinuous operation)

● Avoid dust, oil stains, corrosive gases, places with too much humidity and too strong vibration, and prohibit flammable gas and conductive dust

● Operating temperature:0 ℃~50 ℃

● Operating humidity:40~90%RH(non-condensing)

● Vibration frequency:less than 0.5G(4.9m/s2)10Hz~ 55Hz(discontinuous operation)

● Avoid dust, oil stains, corrosive gases, places with too much humidity and too strong vibration, and prohibit flammable gas and conductive dust

Drive function description

| Drive function | Instructions |

|

Microstep subdivision setting |

4 microstep subdivisions can be set for the Driver through 2 dial switches SW5~SW6. The Driver shall be stopped while setting subdivision. See driver panel instruction for microstep subdivision settings. |

|

Output current setting |

8 output currents can be set for the Driver through 3 dial switches SW1~SW3. See driver panel instruction for output current settings. |

| Automatic half -flow function |

Automatic half current function can be set for the Driver through switch SW4. OFF means that quiescent current is set to half of operating current; ON means that quiescent current and dynamic current are the same. SW4 shall be set as OFF for general use to reduce heat generation of the motor and the driver and to improve reliability. About 0.3s after pulse train stops, current will automatically reduce 50%(actual value 55%) and theoretically, heat generation will reduce 65%. |

| Signal interface | PULis the negative terminal of pulse signal control; DIR is the negative terminal of direction signal; ENA is the negative terminal of enable signal; OPT is the positive terminal of pulse/direction/enable signal (5V public terminal). |

| Motor interface | A+ and A- connect to positive and negative terminals of A phase winding of stepper motor; B+ and B- connect to positive and negative terminals of B phase winding of stepper motor. When A and B phase windings are switched, the Motor direction will be reversed. |

| Power connector | DC power supply, operation input voltage range: 18V-36VDC, 24V DC is suggested |

| Indicator light | There is 1 green indicator light and 1 red indicator light on the Driver. The green one is power indicator light, it illuminates when the Driver is connected to power supply; the red one is failure indicator light, it illuminates when over-voltage or over-current failure occurs.Red indicator ight goes off after failure is eliminated. Failure ofthe Driver can only be eliminated by re-connecting to power supply and reusing. |

|

Installation Notes |

Dimensions of the Driver: 86x55x20.5mm, installation pitch of holes: 79mm. Both horizontal and vertical installations can be selected (vertical installation is suggested). The Driver shall be installed closely against metal cabinet for heat dissipation. |

Parameter Setting

Subdivision precision, dynamic and half/full currents can be set for MC425E Driver through 6-bit dial switch as follows:

Working current setting

| Output peak current | SW1 | SW2 | SW3 |

| 0.5A | on | on | on |

| 0.7A | off | on | on |

| 1.0A | on | off | on |

| 1.3A | off | off | on |

| 1.6A | on | on | off |

| 1.9A | off | on | off |

| 2.2A | on | off | off |

| 2.5A | off | off | off |

Installation size (unit: mm)

Microstep subdivision setting

| Steps/revolution | SW5 | SW6 |

| 400 | on | on |

| 1600 | off | on |

| 3200 | on | off |

| 6400 | off | off |

Lichuan Factory Production Products Machine

-

Carving Machine -

Coating Equipment -

Fiber laster Marking Machine -

Screwing Machine -

Testing Machine -

UV Printer

-

Automatic Soldering Machine -

Holding Torque Testing Machine -

Screw Machine -

Oscillograph Machine

Industry Applications

-

Robotic Arm -

Laser Cutting Machine

-

3D Printing -

CNC Machine -

Automatic Assertmbly -

Engraving Machine

Hot Tags: Ultra Smooth 2 Phase Hybrid Stepper Motor Driver, China, Manufacturers, Suppliers, Factory, Customized, Made in China, Cheap, CE, Durable, Quality

Related Category

2 Phase Hybrid Stepper Motor Driver

3 Phase Hybrid Stepper Motor Driver

2 Phase Stepper Driver Mini

2 Phase I/O Control Stepper Driver

Send Inquiry

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.